The aviation industry aims to achieve climate neutrality starting from 2050. But this ambitious target calls for new aircraft technologies. Why does Airbus believe hydrogen is one of the most promising zero-emission technologies? How would it impact airports? And what are the challenges, different technologies and designs under study? From hydrogen storage, cost and infrastructure to perceptions about safety, the aviation sector is working to mature the technology while tackling some major challenges.

Why hydrogen?

Research into hydrogen to power future zero-emission aircraft has been intensifying in recent years. Since 2010, Airbus has been focusing on zero-emission technologies, starting with its electric flight research and development that resulted in one- to four-seater aircraft and eVTOL (electric Vertical Take-off and Landing) demonstrators. However, larger aircraft require a very high energy-per-unit mass and a deliverable solution within an ambitious timeline.

At Airbus, we strongly believe renewable energy needs to power future aviation. And hydrogen is potentially the best pathway through which to do so.

Glenn Llewellyn, Airbus VP of Zero-Emission Aircraft

The reasons behind this conviction are simple. Hydrogen can mean zero CO₂ emissions if it is generated from renewable energy through electrolysis. Hydrogen may also enable a significant reduction, or even the elimination of Nitrogen Oxide (NOx) and contrails. And as hydrogen production increases, so costs could decrease, making it more and more cost-competitive with existing options such as jet fuel.

The impact: working with airports, airlines and other partners

The key motivation for transitioning to hydrogen is to significantly reduce aircraft’s CO₂ emissions. But this change will inevitably have a massive impact on the entire aviation industry, from aircraft design and industrialisation, to ground and flight operations, and to infrastructures throughout the ecosystem.

Hydrogen could decarbonise future aircraft emissions but could also help decarbonise air transport activities on the ground. Airport-controlled activities account for around 2-3% of the aviation industry’s total emissions.* This represents approximately 15–20 megatons of CO₂ emissions per year globally.

Airports are therefore beginning to rethink their infrastructure design and operations to reduce their overall environmental footprint. One option is to build a unique airport ecosystem with hydrogen at the core of operations.

In 2020, Airbus launched "Hydrogen Hub at Airports" to help airports reflect on how to do just that. The concept aims to jumpstart research into infrastructure requirements for future hydrogen aircraft, as well as low-carbon airport operations, across the entire value chain. And a variety of airport authorities, airlines and energy providers are already signing on to get involved.

Airports have a key role to play to enable the transition to a climate-neutral air transport ecosystem. Hydrogen Hub at Airports enables us to collaborate with partners to define needs today, so we can pave the way for hydrogen adoption by 2035.

Lionel Cousseins, ZEROe Market Development and Airline Relations Manager

Airports are complex infrastructures that rely on deep interdependencies between multiple systems, structures and stakeholders. These include ground transport at airports for passenger transport via buses, but also heavy-duty vehicles for logistics. Traditionally, these vehicles have been powered by fossil fuels, which contribute to overall airport emissions. But hydrogen could drastically cut the emissions of airport ground transport. In addition, airports require vast amounts of energy for cooling and heating, the environmental footprint of which could be mitigated through hydrogen.

This concept involves collaborating with airports to develop a stepped approach to decarbonise airport facilities, ground operations and transport using hydrogen.

The on-site production (and liquefaction) of hydrogen could also be a promising option for airports to meet their individual energy needs. This solution would eliminate the need for transport to and from off-site hydrogen production facilities, which would further reduce emissions. In doing so, airports could also become future energy ecosystems with liquid hydrogen production at their core.

Airbus is working with airline customers easyJet* and SAS Airlines** to assess hydrogen infrastructure needs at airports, as well as airport infrastructure requirements for future hybrid, electric and hydrogen aircraft. The results of both studies should be expected in 2021.

But airline partnerships are only just the beginning. For hydrogen to meet its full potential, the entire airport ecosystem – airport authorities, energy suppliers, regulatory authorities – needs to come together to collaborate. To this end, Airbus has signed a joint-partnership*** with ADP (Paris Airports) and Air Liquide to better understand hydrogen infrastructure needs at Paris Charles-de-Gaulle Airport (CDG) and Paris Orly Airport (ORY). Additional strategic partnerships are expected with key players across the aviation ecosystem in markets worldwide throughout 2021.

Adopting hydrogen - the challenges

Challenges for the industry range from hydrogen storage, cost and infrastructure to public perceptions about safety.

From the technical side, aeronautical engineers will need to adapt the technology to commercial aircraft operations, notably by bringing down the weight and cost.

Extensive safety precautions are already taken in the design and operation of today’s kerosenepowered aircraft. This stringent approach has ensured the industry’s consistent safety record throughout the years. Future hydrogen-propulsion systems will thus need to achieve at least equivalent safety standards before hydrogen-powered aircraft can fly.

Sourcing and cost

Today, more than 70 million tonnes of hydrogen are produced every year, the primary extraction source of which is natural gas (i.e. grey hydrogen). When extracted via fossil fuels, hydrogen production is energy-intensive, responsible for around 830 million tonnes of CO₂ emissions per year. However, electrolysers powered by electricity generated from renewables offer a low-emission alternative. This process, resulting in “green hydrogen,” involves water electrolysis to extract hydrogen.

Less than 0.1% of global dedicated hydrogen production today is considered green hydrogen but that could change. Between 2014 and 2019, global wind electricity production doubled while global solar electricity production quadrupled. The International Energy Agency (IEA) predicts the rapid market growth of renewables, particularly solar and wind, over the next decade will exponentially increase the availability of renewable electricity, thereby driving down its cost. And demand for electrolysers capable of producing green hydrogen is already growing rapidly with an expected electrolyser capacity of 40 GW in the EU by 2030. The increased availability of green hydrogen will thus help to decrease its cost by as much as 30% by 2030 and 50% by 2050.

Ensuring availability at airports

But for hydrogen to really achieve widespread adoption across the aviation industry, it must be made available at airports worldwide.

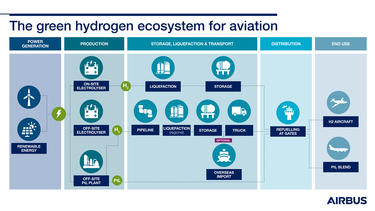

One main challenge is developing the large-scale transport and infrastructure solutions required to supply airports with the necessary quantities of hydrogen needed to fuel aircraft.

A recent IEA* study suggests that repurposing existing infrastructure, including the millions of kilometers of pipelines used today to transport natural gas, could be a cost-effective solution. Larger quantities of hydrogen could thus be transported via pipeline from production sites, while smaller quantities could be transported by truck. In addition, some airport locations could develop the necessary infrastructure to support on-site hydrogen production, particularly if a renewable energy supply is within close proximity.

*IEA – International Energy Agency

Airbus is currently collaborating with both airports and airlines to ensure the necessary hydrogen infrastructure is in place. This includes research into how all airport-associated ground transport (i.e. cargo trucks, passenger buses, aircraft tugs, etc.) could be decarbonised throughout the 2020s timeframe using a stepped approach, which is expected to pave the way to hydrogen availability for aircraft over the 2030s timeframe.

Storing hydrogen safely on board

Combustion involves releasing energy from a fuel and air mixture. In the case of hydrogen combustion, liquid or gaseous hydrogen is burned in a modified gas-turbine engine to generate thrust. This process is identical to traditional internal combustion, except hydrogen replaces its fossil fuel counterpart. And hydrogen has many unique properties that make it suitable for combustion.

The challenge is how to store hydrogen on board the aircraft. Today, liquid hydrogen storage is among the most promising options, while storing hydrogen as compressed gas poses challenges with current aircraft weight and volume requirements.

For liquid hydrogen, tanks need to be insulated to avoid evaporation if heat is carried over into the stored content by factors such as conduction. This is why the Airbus Defence and Space’s Engineering Division has stepped in to help. The team will provide support for the development and industrialisation of cryogenic tanks for liquid hydrogen storage in a three-year project collaboration with the Airbus ZEROe concept plane programme team.

The space industry has been using pressure vessels for the storage of liquid propellant to fuel space exploration for decades [...] So we have a lot of expertise in damage tolerance, in advanced manufacturing technologies and in vessel pressure testing, all of which is key to supporting the development of liquid hydrogen storage tanks for future aircraft propulsion systems. It’s cross-industry collaboration like this that will bring us closer to putting a hydrogen-powered aircraft into the skies over the next decade.

Renato Bellarosa, Head of Propulsion Products and Tanks at Airbus Defence and Space

Changing public perception

For over 40 years, hydrogen has been safely used in vast quantities as an industrial chemical and as fuel for space exploration. In fact, several million cubic meters of hydrogen are transported and handled every year. However, public perception on hydrogen’s safety is still mixed.

As hydrogen increasingly becomes a mainstay in the development of new transport solutions like cars and buses, public perceptions on hydrogen are likely to change – which should positively influence hydrogen adoption in aircraft.

READ MORE, INCLUDING SOURCE DATA

Hydrogen technologies and aircraft designs

Fossil fuels (kerosene and gas) have a high energy density that enables them to power large aircraft over long distances. Sustainable aviation fuels are a clean substitute to fossil fuels, providing immediate but incremental reduction in CO₂ emissions. Similarly, battery-powered electric propulsion has the potential to eliminate emissions. Traditional batteries, however, are heavy and limited in range, which means the power-to-weight ratio makes it difficult to scale up to larger aircraft.

Hydrogen is a gaseous substance that emits no CO₂ if generated from renewable energy through electrolysis. In this case, water and heat are the only by-products, a process through which no emissions other than water vapour are produced.

Hydrogen is also an energy carrier that can stabilise electricity networks provisioned by renewable or carbon-free sources, such as wind turbines and solar panels. Because renewable hydrogen draws on renewable energy sources, it is considered as “cleaner” and more sustainable than comparable energystorage systems.

Engineers have identified three hydrogen technologies that could play a role in fuelling future aircraft:

- Hydrogen combustion in modified gas-turbine engines

This works in the same way as conventional internal combustion which generates motive power (thrust) by burning gas, kerosene oil or other fuel. In this case, hydrogen (liquid or gas) simply replaces its fossil-fuel counterpart.

- Synthetic fuels

This net-zero carbon fuel is created when hydrogen produced via renewable electricity is combined with carbon dioxide. This fuel can already be added to fossil fuels and used in conventional jet engines.

- Hydrogen fuel cells

This technology converts energy stored in molecules into electrical energy. During oxidation, hydrogen atoms react with oxygen atoms to form water, a process during which electrons are released and flow through an external circuit as an electric current to potentially power an electric or hybrid-electric propulsion system.

Airbus ZEROe concept aircraft

Airbus has developed ZEROe concept aircraft to explore configurations and technologies. All three aircraft are hybrid-hydrogen. They are powered by hydrogen combustion through modified gas turbine engines. Liquid hydrogen is used as fuel for combustion with oxygen.

Watch out our "Introducing #ZEROe" Youtube video

- Turboprop configuration: Two hybrid-hydrogen turboprop engines, which drive eight-bladed propellers, provide thrust. The liquid hydrogen storage and distribution system is located behind the rear pressure bulkhead.

- Blended-Wing Body configuration: The exceptionally wide interior opens up multiple options for hydrogen storage and distribution. Here, the liquid hydrogen storage tanks are stored underneath the wings. Two hybrid-hydrogen turbofan engines provide thrust.

- Turbofan: Two hybrid-hydrogen turbofan engines provide thrust. The liquid hydrogen storage and distribution system is located behind the rear pressure bulkhead.

Exploring hydrogen fuel cells

Hydrogen fuel cells are a high-potential technology that offers significant energy efficiency and decarbonisation benefits. Similar to batteries, a fuel cell converts energy stored in molecules into electricity through an electrochemical reaction.

Fuel cells that use pure hydrogen are carbon-free. They do not require recharging and continue to generate electricity as long as a fuel source (hydrogen) is provided. Individual fuel cells can be “stacked” to form larger systems capable of producing more power, thereby allowing scalability. Because there are no moving parts, fuel cells are silent and highly reliable.

In fact, Airbus’ ZEROe concept aircraft is expected to use hydrogen fuel cells to create electrical power that complements the modified gas-turbine engines, resulting in a highly efficient hybrid-electric propulsion system. To further explore the possibilities of fuel cell propulsion systems for aviation, Airbus has entered into a strategic partnership with ElringKlinger, a company with over 20 years of experience as both a fuel cell system and component supplier.

Battery-powered propulsion to fuel larger aircraft over longer distances is not possible with today’s technology, [...] Hydrogen fuel cells could be a great alternative because they can generate—with zero emissions—significantly more power and energy for a given weight. This makes fuel cells an extremely interesting technology to achieve our ambitions.

Matthieu Thomas, ZEROe Aircraft Lead Architect

The hydrogen pod configuration

Hydrogen fuel cell technology has yet to be scaled up to a passenger-size large commercial aircraft. Smaller experimental hydrogen aircraft, comprising up to 20 seats, can rely on a traditional fixed-wing configuration with two propellers. But more passenger capacity and longer range require another solution. This is why Airbus is studying a variety of configurations, including “pods,” to determine which option has the potential to scale up to larger aircraft.

The ‘pod’ configuration is essentially a distributed fuel cell propulsion system that delivers thrust to the aircraft via six propulsors arranged along the wing, [...] Hydrogen fuel cells have very different design considerations, so we knew we had to come up with a unique approach.

Matthieu Thomas, ZEROe Aircraft Lead Architect

Hydrogen has been safely used in the aerospace and automobile industries for decades. The aviation industry’s challenge now is to take this zero-emission energy carrier and adapt it to commercial aviation’s needs.

Airbus expects to decide on the best hydrogen technologies by 2025 and to develop a zero-emission commercial aircraft by 2035. Its ZEROe concept aircraft are about exploring different configurations and hydrogen technologies for hybrid-hydrogen aircraft. Hydrogen fuel cell energy complements the gas turbine, resulting in a highly efficient hybrid-electric propulsion system. All of these technologies are complementary, and the benefits are additive.

Renewable hydrogen is expected to be a solution for several industries to meet their climate targets. Hydrogen has the potential to reduce aviation’s CO2 emissions by up to 50%. Wide collaboration across the industry, including energy providers and airports, is essential to move towards climate-neutral aviation.

To view other FAST articles, download the FAST app (App Store and Google Play) or click here.