Laboratory Testing

As a fundamental part of any engineering solution, we understand the importance of collecting the most accurate test data. We open up Airbus laboratories and engineering expertise in order to first assess your test scenario with expected measurements and accompany you during the test itself. Whether you are looking for wind tunnel, structural, vibrational or even fire testing, Airbus Engineering & Design Services can provide you with the most appropriate test means.

Our advanced material services offer a wide range of Additive Manufacturing solutions and expertise, with the option to receive a prototype in a short timeframe. Our facilities have Direct Energy Deposition and Powderbed capability.

If you have an idea or vision that you wish to take to the next level & develop into a product, our Protospace facility is able to provide the perfect environment. Protospace is the place to go for anyone wanting to validate new ideas, and develop new and better products.

Please contact us. We may have the right test means or facility to address your needs.

Structures & Material Services

We are able to offer structural and materials testing and also Additive Manufacturing services. Our structures test portfolio consists of three test centers in the United Kingdom, France and Germany. All our facilities offer unique capabilities.

Main advantages:

- Fully customisable structural testing capability

- Advanced materials analysis laboratory

- High capacity test machine capable of testing up to 25MN

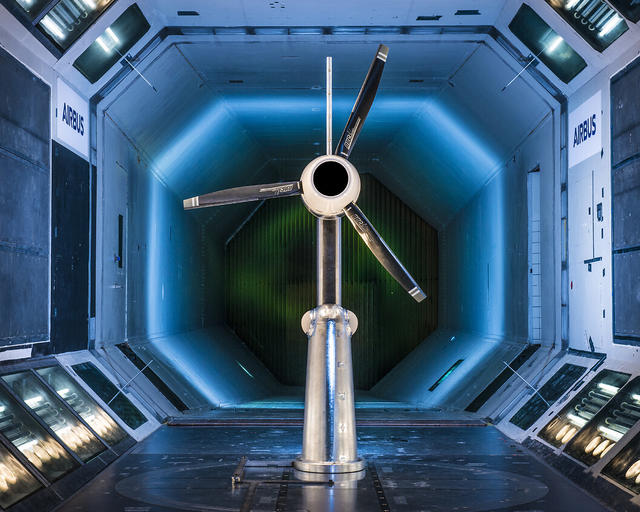

Wind Tunnel Services

Using the expertise from our aerodynamic teams located around Europe, we can respond to varied testing needs, complex requirements and short turnarounds. Our offer can include the following services:

- Rental of the facility

- Prototyping of test specimens

- Data analysis of the wind tunnel test

Benefits:

- Customers get access to Airbus expertise in aerodynamics and support throughout the development of the project

- End-to-end process of design, structural analysis, manufacture, operational testing and analysis of wind tunnel models

- Extensive instrumentation options and experience, applicable not just to the aeronautical industry

- Flow visualisation techniques

Specifications:

- Working section of up to 3.05m (h) by 3.65m (w) by 8.5m (l)

- Speeds up to 97m/s (0.29 mach) (work packages including higher speed or higher Reynolds number work can be led by us with the customer at external wind tunnels)

Environmental & Climatic Testing

We deal here with a unique expertise issued from a wide range of environmental simulation tests performed to demonstrate the certification of aircraft equipment and systems against international certification standards, being representative of the most harsh flight and operations conditions such as over-pressure & vacuum, wide temperature range, thermal shock, high humidity range or corrosion.

Contact us now to see how you can benefit from this unique Airbus capability.

Test means examples:

- Multi Climate Chamber (11.5m x 7.8m x 7.1m) where we can handle 2 different temperature zones (+5°C/+50°C and -60°C/+50°C) with relative humidity of 5 to 100%rH @ 24°C

- Vacuum chamber (5m x 2.8m x 2.6m) where we can achieve temperature range of -70°C to +80°C, low pressure of 115 hPa, relative humidity max 95 % @ 75°C and rapid decompression from 752.6 hPa to 116 hPa within 15 seconds

- Other means/chambers available

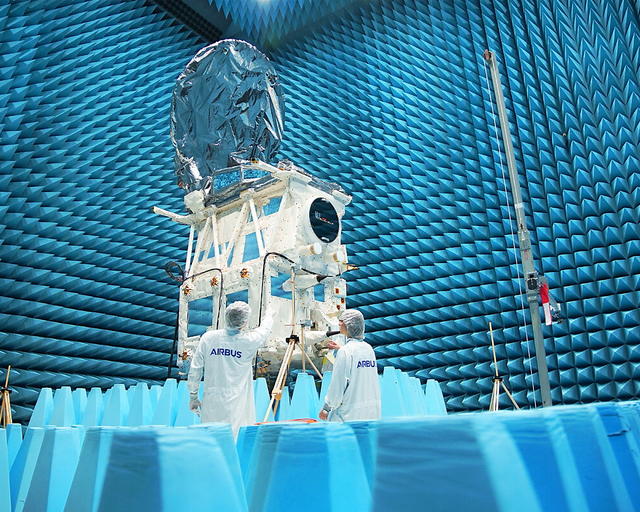

Electromagnetic Testing

Our expertise in the field of Electromagnetic Compatibility (EMC) testing allows us to offer a wide range of tests to qualify and certify equipment and systems against standards applicable not just to the aerospace industry:

- EMC and high-intensity radiated field

- Lightning indirect effects

- Power, harness and shielding

We perform those tests in our laboratories equipped with large size chambers:

- 2 Anechoic chambers (12m x 6,7m x 6,5m with 3m turntable and 5,6m x 3,7m x 2,9m)

- Shielded room (8m x 4m x 2,5m)

- Reverberation chamber (4m x 2m x 2,5m)

We can also perform tests on site in the frame of aircraft working parties, data transfer measurements and certification, for example. Contact us today to find out how Airbus can help you.

Looking for another kind of Engineering and Design Service?

Contact us

Please contact us. We may have the right test means or engineering expertise to address your needs.