INTELLIGENT AIRFRAME WITH UNPARALLELED AERODYNAMICS

The ‘Airbus Intelligent Airframe’ philosophy focuses on environmental sustainability and high efficiency while significantly reducing the financial and operational impact of maintenance.

Intelligent Airframe

This philosophy focuses on the development and implementation of:

- 70% advanced materials

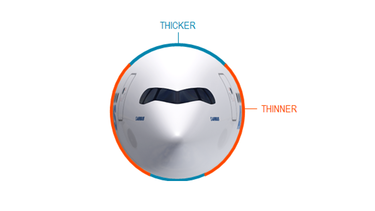

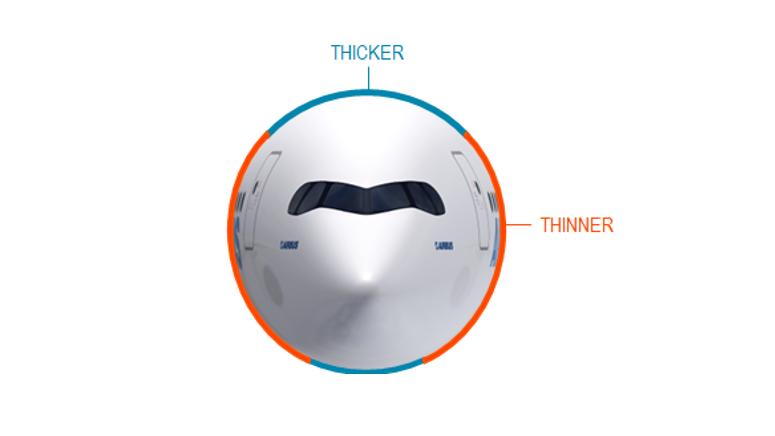

- A new 4-panel concept fuselage

Lightweight and high-strength materials have consistently played a key role in the construction of fuel-efficient and high-performing aircraft.

Airbus has continuously increased the use of advanced and composite materials, with the development of each new aircraft type, eventually culminating with the A350.

With the A350 Family, the outcome is a predominantly composite material aircraft (up to 54%), complemented by titanium and advanced metallic alloys.

The extensive use of advanced materials, together with innovative structural engineering, enables the A350 Operating Weight Empty (OWE) to be 20t lighter than the current 777-300ERs that it replaces.

The 4-panel design enables long fuselage sections thanks to its industrial simplicity compared to the barrel design.

It also enables local thickness optimisation and weight control (thicker on the top and bottom panels where most of the weight stands, and thinner side panels). This design principle makes the aircraft structure optimised and lighter along the fuselage, once again contributing to a lower environmental impact.

Unparalleled aerodynamics

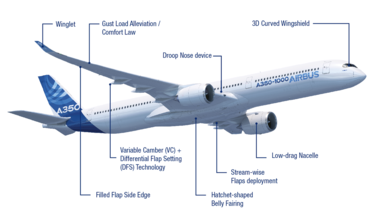

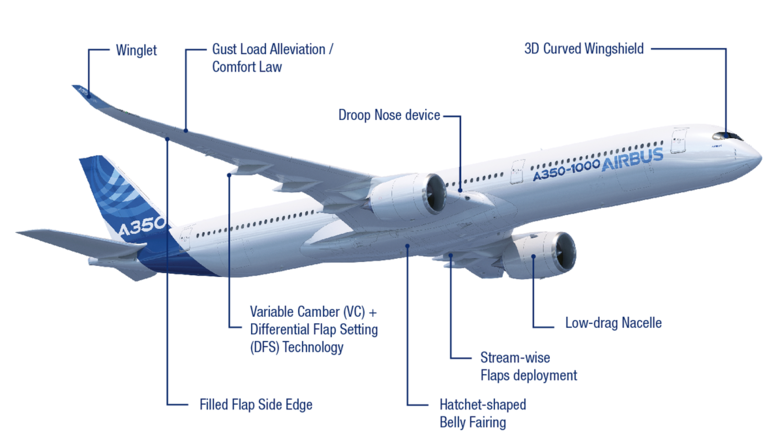

The A350's 64.75m wing-span is designed using nature’s perfect understanding of aerodynamics to maximise lift and reduce drag, further optimising fuel burn and lowering CO2 emissions.

Another wing-design feature is the Variable Camber (VC). The VC allows the flaps to be deflected symmetrically in cruise to optimise the wing profile and better control the longitudinal loads on the wing optimising the lift over drag ratio in cruise. The Differential Flaps Settings (DFS), unique to the A350, optimises cruise aerodynamic efficiency and lateral loads through the control of the wing centre of the lift position where inner and outer flaps are deflected differentially.

Both VC and DFS are fully transparent for the pilots and are embedded into the flight control laws. The overall result is an extremely efficient wing that produces more lift with less weight and is capable of advanced load handling performance that helps to reduce the aircraft’s fuel burn and CO2 emissions.

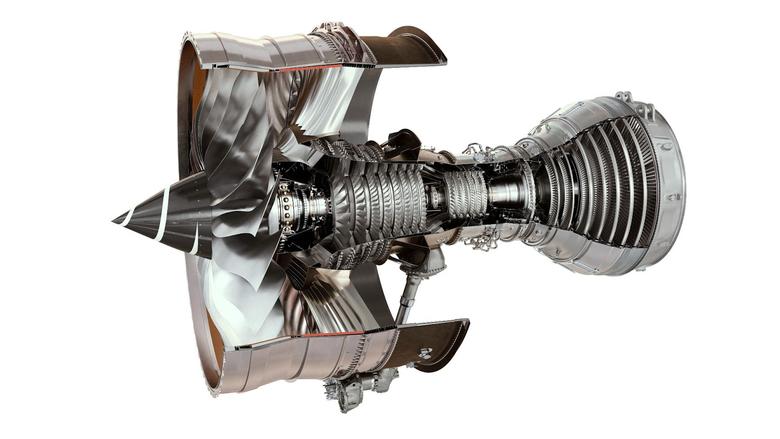

UNMATCHED TRENT XWB ENGINE

The Trent XWB design, using the latest technology, materials and benefitting from over seventy million hours of Trent family in-service experience and with unequalled on-wing reliability, has delivered the world’s most efficient large aero engine flying today.

Its three-shaft design concept is unique to Rolls-Royce and provides better reliability, durability and performance retention.

Further fuel burn and associated cost savings are the result of the Rolls-Royce Trent XWB engine being specifically developed to power the A350 Family.

ADVANCED AVIONICS

The A350 has embedded the latest cockpit features and avionic systems to enable pilot crews to fly the most eco-efficient operations worldwide.

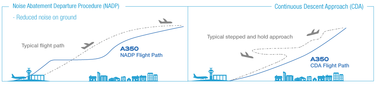

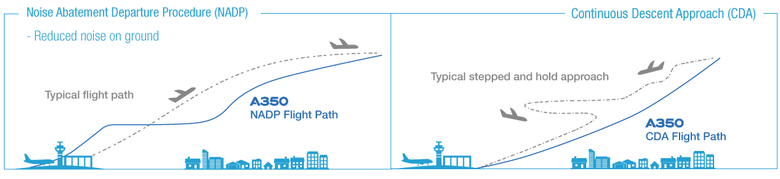

For example, during the take-off phase, the Noise Abatement Departure Procedures on A350s seek to reduce noise over local communities through the use of preferred departure runways and routes, as well as reduced climb thrust settings.

In cruise, the Required Navigation Performance RNP 0.1 helps to optimise routes and approaches, also reducing fuel burn and CO2 emissions.

Finally, at descent, the Continuous Descent Approach reduces noise and fuel burn thanks to a non-stepped descent to landing.

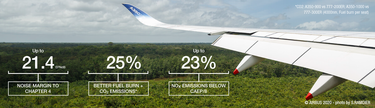

The A350 offers unrivalled operational flexibility and efficiency for all market segments and delivers the lowest noise footprint in its category, reducing the impact on communities.

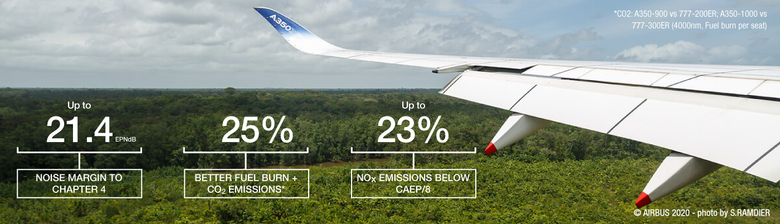

The A350's EPNdB (Effective Perceived Noise Decibel) is certified up to 21.4 below ICAO Chapter 4 noise requirements with its NOx (Nitrogen (di)Oxide) emissions up to 23% below CAEP/8 ICAO standards.