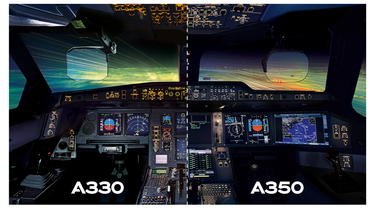

COMMON COCKPIT LAYOUT

From the A320 to the A350, all Airbus aircraft have been developed following the same fly-by-wire philosophy and similar flight deck layouts.

Flight deck commonality benefits

- Shorter trainings for pilots between different aircraft types

- Pilots can hold more than one type qualification

- Reduced number of flight crews

- Higher flight crew productivity

This cockpit commonality allows pilots to move from one aircraft type to another within short training periods and to handle more than one type qualification to fly different aircraft types at the same time. One of the great commonality examples within the Airbus widebody family is with regards the A330 and the A350 cockpit commonality. Airbus has been granted regulatory approval of a Common Type Rating (CTR, difference training course) for A330 and A350, based on handling similarities.

A330 pilots are expected to qualify on the A350 in 8 working days without mandated Full Flight Simulator time. Using the same principle, the A350 pilots can benefit from a reduced Type Rating to be also qualified on A330.

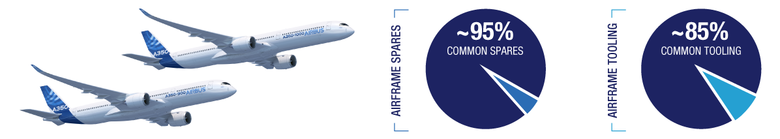

SIMPLIFIED SPARES MANAGEMENT

The commonality philosophy between the A350-900 and A350-1000 also trickles down to the aircraft systems. This high degree of spares and tooling commonality within the A350 Family reduces the associated investment costs when both aircraft types are operated together.

When it comes to maintenance training between different aircraft families (A330 to A350 for example), operators can have their mechanics undergo Cross Mechanic Qualifications, which is essentially a shortened licensed B1/B2 mechanics training between certain aircraft types.

This advantage translates into having a reduction in the number of mechanics by economies of scale and increasing mechanic productivity.

Learn more on Maintenance Training

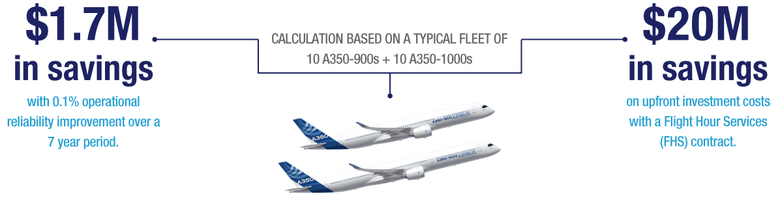

Flight Hour Services (FHS)

FHS-Components is the best solution to further streamline the management of your spare parts, while optimising your costs and transforming your upfront investment from CAPEX into OPEX.

FHS-Components offers guaranteed availability of all primary Line Replaceable Units (LRUs) spare parts, to keep your aircraft flying. It also provides you with exclusive inventory at your main base and selected outstations, backed up by unlimited pool access to deliver a guaranteed service level. In addition, through accurate reliability monitoring, we track and improve your components‘ performance.

MAXIMUM ENGINE COMMONALITY

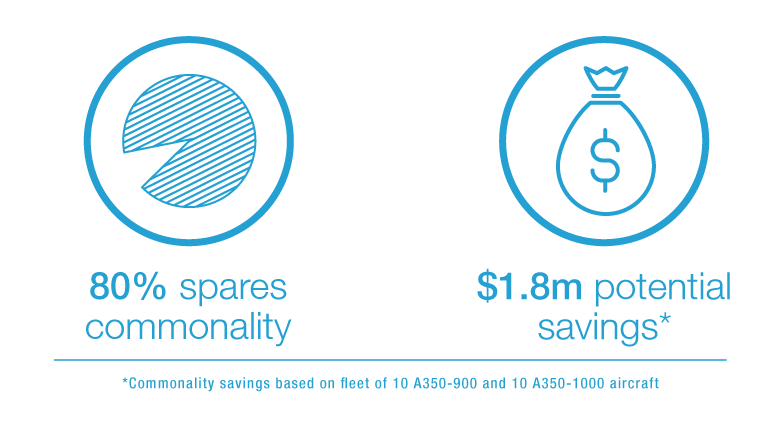

The A350 Family’s commonality reduces maintenance costs not only through simplification of system architectures, maintenance procedures and reductions in spare holdings but also by having the leanest maintenance programme.

The Trent XWB engine has been designed specifically for the A350 and it benefits from an optimised performance and commonality across its two thrust versions, the Trent XWB-84 and the Trent XWB-97.

Optimised commonality contributes to reducing costs and increasing efficiency across LRUs and IP, tooling, training and maintenance procedures, enabling an airline to operate both Airbus A350-900 & A350-1000 within their fleet with maximum efficiency and operability.