Choosing the right options for a new aircraft cabin can be daunting for airline customers. Airbus aircraft cabins have become far more customisable in recent years, leaving customers facing a huge number of choices, but technological innovations are helping to smooth the process.

Thierry explains more:

"People who haven’t worked in an airline cabin, don’t always realise how complex it is.

They can just think it’s about seats, toilets and a galley and that’s it.

But there are also partitions, curtains, storage, lights, air conditioning, cabin communication systems and much more. And there is also a lot of interconnection in the cabin – so there is a domino effect, if you change one option it has knock-on effects elsewhere.

Driving an airline’s choices in the cabin are the different objectives of its teams – so cabin definition means balancing the priorities of management, alongside marketing teams and other airline teams such as cabin crew, catering and engineering.

Each cabin definition project is unique and as detailed as the airline wishes. Airlines’ aims vary depending on their goal as a carrier – for example, whether they’re targeting domestic or international passengers. But they all want to differentiate themselves from the competition. And they are all seeking profitability.

If they are investing a lot in the cabin, they also want a quick return on that investment."

Cabin criteria

There are several variables for airline customers to consider when defining their cabin.

If it’s a big airline, there can be many stakeholders. While with smaller airlines, we are sometimes in direct contact with the CEO or board members. We have many ways to support the customer and we work to balance the best package for them and help them to take a decision.

Alongside the customer’s requirements, there are also regulatory obligations from the aviation authorities and technical constraints from Airbus – for example, not exceeding weight limits. In addition, there can be mandatory operational requirements from the airline to be considered – for example, having a minimum number of trolleys by the aircraft door, or no seats in front of the lavatory entrance.

After that, airlines are looking at points of differentiation for their cabin, features they want for passengers, requirements for cabin crew to perform effectively, and any additional necessities for pilots or engineering and maintenance personnel.

The requirements of airline and Airbus suppliers also need considering. We work in partnership with them to get the required equipment into the cabin.

The layout of the cabin is the main factor as it provides the basis for the cabin definition. This depends on the needs of the airlines, but we also have to consider integration into the aircraft. We’re creating a unique solution for each airline based on its requirement – considering seat models, lavatories, storage etc.

The cabin layout is modified and updated as the project progresses. Usually it’s about finding a compromise that works for the airlines, for example, there is a maximum number of possible seats and galleys. It’s about adapting the original requirement.

Definition Journey

The Airbus teams help guide the customer through the definition process.

After the kick-off meeting, customers have a product offer demonstration at the CDC, where they see the variety of the cabin offer. Suppliers – such as seat manufacturers - are present as needed to explain their products.

After the demonstration, comes the definition meeting. And then at the end is the Cabin Definition Closure Meeting, where we go step-by-step through the definition document. Then we sign the definition document with the customer and suppliers. Based on that document we build the cabin. Once that is done, the delivery centre and other customer teams take care of the delivery phase.

One-stop-shop

In March 2019, Airbus opened its extended Airspace Customer Definition Centre (CDC) in Hamburg for cross-programme cabin customisation including the A320 and A330 Family programmes – alongside the existing A350 XWB Family customisation areas.

Alexander explains:

"The CDC now fully adopts the Airspace cabin brand, (see below “What is Airspace?”) which was first launched with the A330neo, and sets new cabin standards of comfort, ambience, service and design for airlines and their passengers.

Our teams, tools and state-of-the-art technology at the CDC are there to make it easier and faster for our customers to define their cabins.

A customer visit to the CDC typically lasts two to three days, with most visits dedicated to cabin definition although some are to support customer sales campaigns.

Today, many A350 XWB customers are also A320 or A330 operators, so the enhanced centre is a win-win situation for all stakeholders to streamline cabin definition across their fleet.

The CDC is the one-stop-shop for cabin customisation. Customers no longer need to travel to multiple destinations to see suppliers; they now have the CDC that brings together all the right people from Airbus and the suppliers in one place.

Customers can come to the centre and see what their future product will look like – using fully-integrated cabin mock-ups, virtual reality and mixed-reality tools."

Customers can see what their future products will look like:

Using fully-integrated cabin mock-ups, virtual reality and mixed-reality tools, all under one roof

Watch the Airspace Cabin Vision 2030

What is Airspace?

Airspace is Airbus’ innovative cabin brand. Launched in 2016, it was created with passengers at heart and airlines in mind, and built around four key pillars: comfort, ambience, services and design. Signature design elements recognisable throughout all Airspace cabins offer more personal space; larger overhead storage bins; spacious, contemporary and more hygienic lavatories. Other features are personalised in-flight entertainment and connectivity options, a unique and customisable welcome area, the latest in LED technology for ambient lighting; plus straight lines, clean shapes and clear surfaces throughout the interior.

Delivered on Airbus’ A330neo and A350 XWB, and soon to be installed on the A320neo Family, the Airspace passenger experience will be available across the Airbus fleet and benefit travellers on all kinds of routes.

Definition process

Defining a customer’s cabin requirements can take anywhere from 6 months to 2 years.

- Based on initial discussions with the customer, Airbus presents its cabin offer, adapting it to the customer’s objectives.

- The customer works with Airbus on the specificities, progressing step-by-step through each commodity to reach a final decision.

- Both parties fix the main concept of the cabin and requirements, reach the Contractual Definition Freeze (CDF) and sign a contract.

- Airbus assembles the cabin, bringing all the parts into the aircraft before performing the final physical validation with the airline.

Zoning in

In the CDC, the customers are led through specifically designed areas, from the private customer lounge to a hub of meeting rooms, from where they access the centre’s different zones.

Huge screens with virtual reality (VR) capabilities represent a 1:1 scale cabin experience. Using VR goggles, customers can move around a virtual cabin in 3D where their specification has been applied.

From that room, they can move into different functional zones, view the real equipment, access mixed-reality rooms and mock-up rooms, to clarify specific cabin situations further enriching the Virtual Reality. Today, the customer always asks for a combination of VR and hardware - it’s about making the definition as easy as possible for the customer.

Integrated mock-up rooms

When the customer is defining the cabin in 2D and 3D, they typically want to see the real equipment, such as seat options. We have fully-integrated mock-ups for A350, A320 and A330.

Customers can test fully functional seats in a cabin environment, so they can see how they feel in the aircraft. As the CDC is also a partnership platform, suppliers are invited so customers can get their questions answered on the spot.

As they make decisions, the customer’s specification is loaded into a file, with selections added to the 3D model so they can view it in VR. Mock-up zones for different areas of the cabin, such as galleys and lavatories, help customers further define the cabin.

Some customers bring their cabin staff to test out the galleys and equipment, and it becomes a ‘cooking session’ to see how the space and equipment performs.

Over the last few years, cabin lighting options have gained increasing importance alongside material trim and finish. Previously, there were a lot of material trim and finishes - which we still do, but they are more harmonised with lighting as customers take advantage of advanced systems.

We have dedicated mock-ups, where customers can define their lighting scenarios. There are 16.7 million colours in the lighting system on the A350; with the most advanced full LED system, you can enrich atmosphere in an aircraft. Customers can test materials and see how they change the finish of the cabin with different lighting.

Scenario testing

The speed that customers can access bespoke physical mock-ups at the CDC is one of its strengths. One airline customer was able to experience a specific door zone arrangement, taking advantage of VR and hardware.

They wanted to establish if there was sufficient clearance for cabin crew and passengers during the onboarding procedures. We mocked-up the respective door zone including lavatory and galley, as well as the area in front of it, to test the specific layout arrangement. Management and cabin crew came to test it with the onboard furniture and were able to perform the check within one day and validate the definition.

Configuring the layout

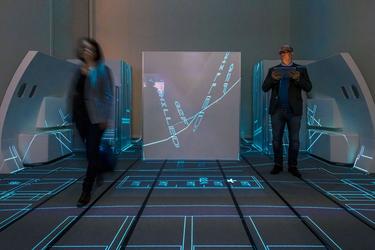

The Configure Room is where customers get more of a feel for the environment and space. This mixed-reality room has projectors in the ceiling, projecting in one-to-one scale the floor layout on the ground – showing galleys, lavatories, seats etc. Alongside original cabin elements and dimension mock-ups, customers can perform tests of alternative layouts and scenarios.

It allows customers to test the space on a functional level, as well as get a sense of the passenger experience. It helps them reach a balance between function and design. They get the impression of space. For example, they can test if a trolley goes smoothly through the aisle or the galley environment.

Customers can control the layout and change it easily. We can re-arrange room and cabin layout on the spot for them. The room is ideal for a group of people moving around together and reaching decisions.

The combination of functional playrooms for cabin equipment testing, exhibition areas for typical airline product staging, design studios for material and mood light definitions, virtual and augmented-reality technology complemented by customer-specific mock-up areas, make a unique space for customers.

The experience at the CDC is always customised, it’s for the customer to decide how to use it. The centre supports a faster process with full transparency and fosters decision-making. We bring all the people with the right knowledge together, so we can clarify things immediately for customers.

Retro-fitting

Retro-fitting a cabin has more technical constraints than line-fitting. We have to take into account the current aircraft we’re going to refurbish and the current specification it has, so there can be additional limitations.

Most of the airlines want to minimise the cost of refurbishment, so they want to use the most cost-efficient modifications – and we can support them to do that.

Customer experience

Morio Suzuki Manager, Interior Group, Engineering Project Office, JAL Engineering (JALEC)

Talks about introducing the A350-900 into Japan Airlines’ domestic fleet.

What are some of the most challenging things about choosing a cabin?

“The most challenging thing is making a seat layout to provide satisfaction and a good cabin experience to our customers. We need to pursue a maximized passenger area within a profitable range and certification restrictions. Airbus’s configuration tool provides lots of help to seek the viable and certifiable layout as it gives warnings when the selected layout goes against certification rules.”

How does the process for cabin definition compare now with how it was 10-20 years ago?

“3D imaging tools and viewers, such as VR, provide advanced experience. Before actual aircraft production, we can feel as if we are actually in the cabin. I remember when I entered the actual A350 cabin, I had a feeling of déjà vu: the actual aircraft was produced as per the image that we saw several months ago in the VR.”

What are JAL’s priorities when defining a cabin?

“Everything is for our customer. The passenger area is the first priority. The second one is the functionality of the seat (electrical motion, IFE, PC power, WiFi).”

Conclusion

Rapid solutions for customers

Cabin definition is a complex process with many deliverables. Despite increasing harmonisation of processes and tools, there are a huge number of deliverables to provide the cabin as expected by the airline. The number of interfaces internally and externally, with the airline and suppliers is also complex.

But advances in digitalisation are helping provide tools such as the virtual and mixed-reality mock-ups in the Customer Definition Centre, that make it easier for customers to define their cabin; it is becoming faster and simpler for them every day.

Your media contacts

Contact us

Thierry ORILLAC

A350 Cabin Project Leader | AIRBUS

Alexander JUERS

Project Manager - Customer Definition Centre | AIRBUS