On aircraft, cabin air quality contributes significantly to the comfort and well being of passengers and crews alike. But what is actually cabin air quality, what is the importance attributed to cabin air quality in aircraft design and operation, and what is Airbus doing to preserve good air quality in the aircraft cabin? Let’s take a journey into the technical depths of the rather abstract term of “cabin air quality”. And in the context of COVID-19, check the facts about cabin air and listen to the podcast from Executive Vice President Engineering at Airbus on why it is safe to fly.

Revised article from FAST 50, April 2014. Includes updated information and a Covid-19 focus.

Aircraft operating environment

Civil aviation occupies a position of particular importance among modes of public transportation, due to its environmental and operating conditions. Commercial aircraft operate primarily in the troposphere* and lower stratosphere*, depending on their geographic position. This is an environment that is hostile to life. The outside temperature can drop to below -50 °C, the ambient pressure can decrease to less than 200hPa (hectopascal), which is one fifth the ambient pressure on the surface of the earth and high ozone concentrations may occur.

The aircraft cabin becomes increasingly part of our normal habitat and is therefore subject to high expectations. Besides the ergonomic design and the amenities, there are also other factors with an impact on passenger and crew well-being that we have to take into consideration. Air quality, temperature and pressure are important parameters which are directly controlled by environmental control systems.

Definition of cabin air quality

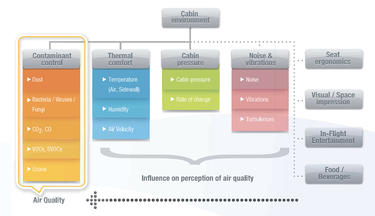

As indicated in figure 1, cabin air quality is defined by the content of gaseous, particulate and biological contaminants in the air. Besides this, other factors like temperature, humidity or even aircraft movement can have an influence on our perception of air quality. Such influences and real air contamination issues are difficult to disentangle, and physiological perceptions cannot generally be attributed to airborne contaminants.

*Troposphere: The lowest region of the atmosphere between the earth's surface and the tropopause, characterised by decreasing temperature with increasing altitude.

Tropopause: The boundary layer between the troposphere and stratosphere. It is defined as the lowest level at which the temperature lapse rate decreases by 2°C km-1 or less, to reach an average of -56°C.

*Stratosphere: The region of the atmosphere above the troposphere and below the mesosphere.

Figure 1. The cabin environment and its influencing factors

Cabin air quality in the aircraft environmental control design

The most effective approach for removing contaminants is by air exchange. Outside air which is usually very clean, particularly during flight, is conveyed into the pressurized fuselage and approximately the same amount is discarded overboard by the environmental control system. The entire cabin air is exchanged volumetrically with outside air every about two to three minutes. As a prerequisite to maintain excellent air quality aboard aircraft, it is necessary to assure cleanness of the air delivered to the cabin. Consequently, it is important to know where the air is coming from and which way it moves from the outside environment into the cabin.

An aircraft environmental control system performs three main tasks:

- It supplies fresh air and, in connection with this, removes air pollutants from the cabin replacing used air.

- It pressurises the aircraft fuselage.

- It controls the temperature in the cabin and cools technical equipment.

During flight, pressurised outside air is taken from the compressor stage of the engines (bleed air) upstream the combustion chamber, where temperatures up to 400°C can be reached, then is passed through a pre-cooler unit and conveyed to the air conditioning packs at a temperature of approximately 200°C. Alternative bleed air supply sources during ground or ground near operations supplying the air conditioning packs with pressurised and consequently hot bleed air, are Auxiliary Power Units (APU) and High Pressure Ground Carts (HPGC).

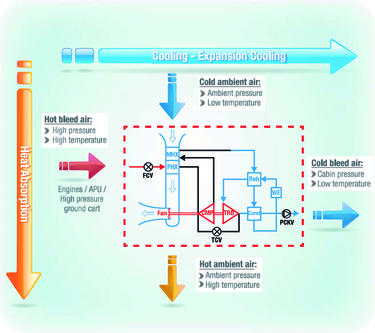

The air conditioning pack (figure 2) cools the air to the required temperature using outside air (ram air) as the cooling medium and air cycle machines for compression and expansion cooling. This basic architecture is still the best proven technology for aircraft air conditioning systems with regards to efficiency, flexibility, reliability, installation space and maintenance costs.

Figure 2. Basic principle of an aircraft air conditioning pack

Cond: Condenser; CMP: Compressor; FCV: Flow Control Valve; MHX: Main Heat Exchanger; PCKV: Pressure ChecK Valve; PHX: Primary Heat Exchanger; Reh: Reheater; TCV: Temperature Control Valve; TRB: Turbine; WE: Water Extractor.

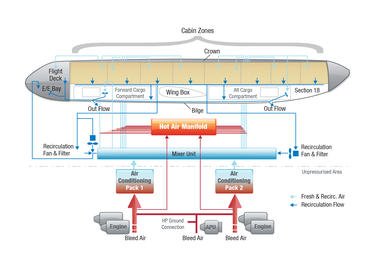

A mixer unit, installed below the cabin floor in front of the centre wing box, mixes outside air with cabin air. The cabin air is taken from the under-floor area and drawn through recirculation filters by recirculation fans (figure 3). The quantity of recirculated cabin air mixed with the outside air varies from 40% to 60% and improves efficient removal of heat loads at a moderate temperature gradient and increases the humidity by making use of the cabin air. The latter contains humidity contributed by the passengers whilst outside air, being very cold, is almost completely dry. After leaving the mixer unit, the air is distributed to different cabin zones. For each cabin zone a different temperature can be selected. Trim air valves regulate the cabin outlet temperature by injecting small amounts of hot bleed air from the pre-cooler outlet (trim air).

Figure 3. Example of an aircraft air generation and distribution system

Air cleaning technologies

Besides the air exchange with the outside air for efficient contaminant removal (most importantly CO2 and other bio-effluents), additional technologies are necessary to avoid exposure to ozone from the operational environment and to exclude distribution of biological pathogens in the cabin by recirculated air.

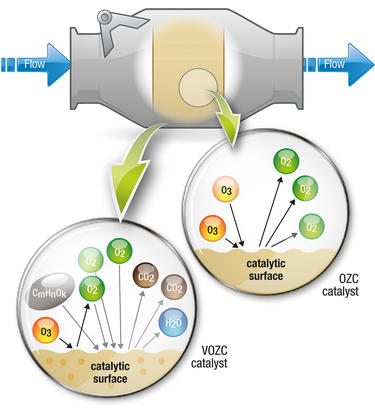

During cruise at high altitudes - in particular on polar routes - the outside air may contain significant concentrations of ozone. To ensure a sufficiently low ozone concentration in the cabin, long-haul service aircraft, and even most of the short-haul service aircraft, are equipped with catalytic ozone converters (figure 4). The ozone converters are installed in the bleed air, ducting upstream to the air conditioning pack to ensure sufficient temperature levels for the catalytic process. Modern ozone converters, as introduced by Airbus in 2004, combine the ozone conversion with the ability to mitigate odorous compounds from kerosene external vapours, which might occur during ground operations, to improve the olfactory* perception.

* Olfactory: Relating to, or contributing to the sense of smell.

* Olfactory perception: The sensation that results when olfactory receptors in the nose are stimulated by particular airborne chemicals.

Figure 4. Simplified scheme of ozone conversion (OZC) and combined ozone / VOC conversion (VOZC)

CmHnOx: Simplified molecular formula for organic compounds consisting of Carbon (C), Hydrogen (H) and Oxygen (O) atoms;

CO₂: Carbon dioxide; H₂O: Water; O₂: Oxygen; O₃: Ozone; OZC: Ozone Converter; VOC: Volatile Organic Compound; VOZC: VOC/Ozone Converter

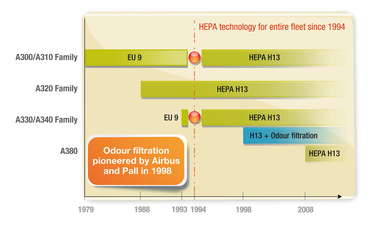

Since 1988 on Airbus single aisle aircraft and since 1994 for the entire fleet (see figure 5), Airbus installs HEPA (High Efficiency Particulate Air) filters for the recirculated air providing more than 99.9% filtration efficiency (for 0.3 micrometer particles as most penetrating particle size). It is important to understand that the filtration efficiency for these filters is not only based on direct interception or sieving for larger particles but also on other effects like impaction and diffusional interception for smaller particles like bacteria and viruses. Consequently even viruses including SARS-CoV-2 are effectively removed by these filters and hence cannot be distributed by the ventilation system.

More about filters

- Are all Airbus aircraft equipped with HEPA filters?

All Airbus aircraft manufactured since 1994 are fitted with HEPA filters. These filters provide the best level of filtration currently available for recirculated cabin air. The Airbus fleet in operation worldwide is equipped with HEPA filters with the exception of a few A310s and A300-600 aircraft. A filter retrofit solution is available for these few aircraft though service bulletin 21-2057 (for A310 aircraft) and service bulletin 21-6046 (for A300- 600 aircraft).

- Are HEPA filters installed only on airplanes with a pressurised cabin?

The technology is not limited to airplanes with pressurised cabins. However, the recirculation concept is mainly used on aircraft with pressurized cabins to improve thermal comfort in an eco-efficient manner. Hence HEPA filters are more common on those aircraft.

- Do HEPA filters have mandatory or periodic maintenance? How often do the filters on planes need to be changed?

The HEPA filters are changed depending on the aircraft type and as specified in the aircraft maintenance programme. This schedule is continuously reviewed in the frame of continuous airworthiness activities. The HEPA filters are changed depending on the aircraft type at a scheduled maintenance time (several thousand flight hours). This schedule is continuously reviewed in the frame of continuous airworthiness activities. It remains the responsibility of the operator to change HEPA filters based on Airbus guidance. - What has improved in recent years in the filter system?

While the HEPA concept is still the most efficient and practical method for removing dust and pathogens from air since decades, a lot of improvements have been made regarding the materials used to improve their durability and performance. Also architectural improvements were implemented to increase the capacity of HEPA filters. HEPA filters are standard on A220, A320, A330, A350, A380 aircraft. Almost all passenger transport aircraft now use HEPA filters. Airbus and Pall Aerospace have developed a combined HEPA / VOC Filter. VOCs and SVOCs normally come from hydrocarbon based fuels, oils or fluids. They can come from exhaust fumes at the airport, or from the aircraft’s own systems in the event of a fault or leakage.

Watch video: Flow and cabin ventilation in an Airbus aircraft: how does it work?

Figure 5. Filtration technology installed on Airbus aircraft for recirculated cabin air

Sustainability of cabin air quality

Within the aircraft, air supply system areas with high temperatures are most critical with regard to air quality because high temperatures would lead to evaporation and possibly to the breakdown of organic substances, if they found their way into the high temperature areas. Consequently, special care needs to be taken to prevent contamination with materials susceptible to evaporation or deterioration at this area during design, manufacturing and operation of the aircraft.

A top priority is clean air supply starting with the sources of pressurized air for the aircraft ventilation, engines, APUs and air conditioning systems. Since the 1990’s, Airbus has defined additional requirements for bleed air cleanness on top of the requirements used for certification of engines and APUs by authorities. Airbus is supporting international research projects and working groups, to acquire independent external expertise and scientific knowledge by promoting best standards for an ideal cabin environment and its verification. Airbus is also involved during validation of the verification strategy with APU and engine manufacturers, while supporting with its own measurements.

These analytical capabilities can also be used to tackle problems that could occur during production flights, which are conducted for each aircraft prior to delivery by Airbus. Any contamination introduced during manufacturing will become apparent when the aircraft air supply system is operated as a whole, and some parts of the bleed air system are subjected to the highest operational temperatures for the first time.

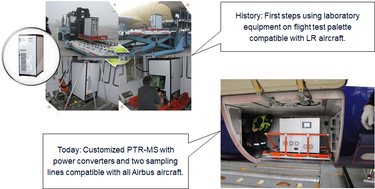

Airbus developed a sophisticated measurement strategy consisting of combinations of online measurements and traditional air quality sampling according to international standards. Online mass spectrometry, as well as multifunctional sampling systems such as Fraunhofer IBP* sampling trolley, can be used to identify and track even small concentrations of pollutants in order to elucidate their origin.

*An automated and self-sustaining sampling system developed by Fraunhofer Institute for Building Physics (Fraunhofer IBP)

The online mass spectrometer used is a unique combination of a Proton Transfer Reaction (PTR) ionisation method with a Time Of Flight-Mass Spectrometer (TOF-MS).

Figure 6. After successful tests with the original laboratory device, Airbus together with Ionicon developed a customised device that is also compatible with the A320 Family

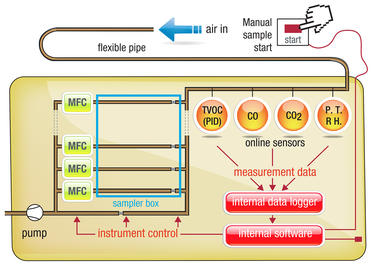

The sampling system developed by Fraunhofer Institute for Building Physics can be installed as a trolley in galley compartments during flight tests (figures 6, 7 and 8). The trolley can contain up to 36 sampling tubes tailored for different compound classes and several sensors (e.g. for carbon monoxide and carbon dioxide). Alternatively, dedicated sampling pumps and monitors can be used in case a trained operator is allowed to be on board during flight (figure 8).

Figure 7. Diagram of sampling trolley with sensors and sampling tubes connected to a vacuum system. The flow through the sampling tubes is controlled by mass flow controllers and initiated by pressing a push button located in the cockpit.

CO: Carbon Monoxide; CO₂: Carbon Dioxide; MFC: Mass flow controller; P: Pressure; rH: relative humidity; T: Temperature; TVOC: Total Volatile Organic Compounds

Figure 8. An automated sampling trolley (left) or dedicated sampling pumps (right) can be installed on aircraft depending on the specific boundary conditions

With this analytical system a marker substance and finally the root cause for a specific contamination during first flights of a particular aircraft type could be identified unambiguously, based on the results of air quality measurements on the aircraft. Knowing the precise root cause and having clear evidence at hand, corrective actions could be implemented at the supplier’s, and be further followed up.

Conclusion

Analytical methods will be further improved and new sophisticated analytical tools are continuously scrutinised to simplify measurements with the ambitious long-term objective to do a complete analysis of the cabin air at the push of a button. Indeed, combining sophisticated measurement technologies with established databases of contaminant patterns would revolutionise troubleshooting and aircraft system monitoring.

Airbus continuously reviews whether any sensing, air filtration or cleaning technology could add value to passengers, crews and aircraft operations. Since the air provided to the cabin during flight is already very clean under normal operating conditions, this means carefully considering technical and environmental repercussions as well as any safety implications. The introduction of such technologies needs to be thoroughly justified.

Rational decisions in design and operation of aircraft are essential to safe air travel. Considering that civil aviation is still the safest mode of public transportation, this basic principle is and remains key.

Special COVID-19 focus

Listen to podcast: Jean-Brice Dumont, Executive Vice President Engineering at Airbus, explains what High Efficiency Particulate Air (HEPA) filters are, and why the air in the cabin is clean.

10 facts about clean air on board

- Airbus aircraft design meets requirements exceeding compliance with airworthiness regulations to provide the highest level of cabin air quality, and designed to prevent air contamination under normal operating conditions.

- Airbus, along with many industry partners and regulatory agencies, continually examine all aspects associated with the cabin environment and in particular the eventuality of related health effects.

- At 10,000 m cruise altitude, the air is very dry and very cold (-50°C). Hence, the air ventilation systems need to transform it in order to provide regulated and fresh air with adequate temperature, pressure, oxygen and humidity.

- The air in Airbus aircraft cabins is a mix of fresh air drawn from outside, and recirculated air that has been passed through extremely efficient filters, which remove particles in the air down to the size of microscopic bacteria and virus clusters.

- HEPA filters used in Airbus aircraft remove more than 99.9% of micro/nano particulates, viruses and bacteria.

- None of the air that is supplied to aircraft toilets, galleys and cargo-holds is recirculated into the cabin – instead it is dumped directly overboard.

- Air in Airbus cabins is renewed about every 2-3 minutes.

- Conditioned air enters the cabin via numerous air inlets at the top of the cabin and leaves at floor level and is designed to prevent longitudinal airflow within the cabin.

- The airflow induced by the cabin recirculation fans is designed to assist in maintaining the correct cabin airflow pattern.

- At seat level, there is a constant downward wash of air at 1 m/s.

Airbus is working with industry partners and regulatory agencies to examine the end-to-end travel experience and ensure it continues to be healthy and safe.

Everyone - from airlines, pilots and crew, to members of the airport community, authorities, and travellers - needs to adopt health and safety routines when travelling. Whether it is on the way to or at the airport, behind the scenes at baggage, ground, and cargo handling or for cabin crew and pilots, everyone needs to play an active role to get back to the skies and maintain trust in air travel.

Visit airbus.com to read more on keep trust in air travel.

Your media contacts

Contact us

Andreas Bezold

Expert - Cabin Air Quality - Ventilation Systems AIRBUS