Since its first delivery in November 2018 and with over 120 aircraft in service today, the A330neo Family has already received various incremental improvements. These include: a maximum take-off weight (MTOW) increase from its originally certified 242 metric tonnes to 251 tonnes; certification to ICAO’s 2028 CO2 emissions standard; higher “Max-Pax” capacity increase for the A330-900 from 440 to 460 seats in nine-abreast all-economy; as well as a Trent 7000 HP-turbine engine durability enhancement package from Rolls-Royce – doubling the in-service blade life for increased time-on-wing.

Continuing the A330neo’s evolution trend: From around Q4 2025, customers will be able to take delivery of an aircraft with even more operational performance and flexibility thanks to the next incremental package, referred to as “Step 4”. This will focus on enhancing the aircraft’s low-speed performance. This is achieved by further maximising lift and reducing drag during the take-off and subsequent climb-out phases.

Enhancing take-off performance for greater uplift

With the Step 4 package A330-900 operators will be able to benefit from an extra take-off-weight uplift capability of around 2.6 metric tonnes at some airports, while at other, even more runway-restricted airports, the net gain could be as much as four tonnes – and all without increasing the engine’s thrust. Airports where such operators could expect gains include: Madrid, Minneapolis, Reunion, Dusseldorf, Bogota, Gatwick and Mumbai – among others.

It should be noted that the drag reduction and lift improvement are achieved by two main enablers used together: The first is the provision of some intermediate flap settings, known as ‘Enhanced Take-Off Configurations’ (ETOC). The second enabler is the implementation of faster landing gear + landing gear door retraction sequences. These are respectively described below.

Enhanced Take-Off Configurations with new intermediate flap and slat settings

To understand how ETOC works, one first needs to understand that today the A330 and A320 Families’ common-cockpit has five flap/slat lever settings: Flaps-0 being fully retracted, thru positions -1, -2, -3, and finally ‘Full’. On take-off the flap setting chosen depends on the available runway length and engine thrust settings – plus other factors such as second-segment climb obstacle clearance etc.. In general, the higher the flap setting the greater is the associated lift produced during take-off. However, a higher flap setting also naturally creates more aerodynamic drag (which could impact the aircraft’s acceleration), especially during the initial climb phase. Therefore, if the runway length allows, a lower flap setting is usually preferred. Thus “Flaps-Two” is a typical setting, since it provides a good balance between extra lift needed for take-off and lower drag for the subsequent accelerating climb-out whilst maintaining the required flight-path angle.

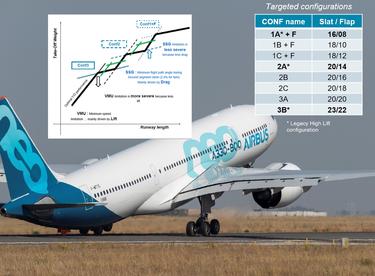

Nevertheless, since there is still quite a significant aerodynamic ‘jump’ between each of the respective five flap-lever settings today, Airbus has identified scope for further performance optimisation and smoothing-out the flap and slat transitions by introducing intermediate ‘bridging’ flap positions – ie. slotting between Flaps-One and Flaps-Two, and between Flaps-2 and Flaps-3 and Flaps-Full respectively.

To this end, engineers on A330neo programme have developed ETOC which requires no physical changes to the aircraft: From next year, pilots of newly delivered A330-900s will be able to enter the intermediate flap settings into the Multi-Function Control & Display Unit’s (MCDU) ‘Performance’ page. The four extra flap positions (in addition to the existing five flap lever settings) are denoted as: 1B, 2B, 2C and 3B – making nine positions in total. The particular take-off flap setting and corresponding take-off ‘V-speed’ values will be provided to the pilot by the Electronic Flight Bag’s (EFB’s) runway performance calculator app.

Once flap levers are set (eg. to 1+F, -2, or -3), the aircraft’s avionics will automatically move the slats and flaps on the wing to the desired intermediate position (eg. Flaps-2A / 2B etc.) for take-off – as set already in the MCDU. For ETOC implementation, there are no physical changes to the actual flap-lever itself. However, some avionic computer hardware modifications are also required, such as to the ‘Flight Management Guidance and Envelope Computer’ (FMGEC).

Faster and earlier landing gear & door retraction sequencing

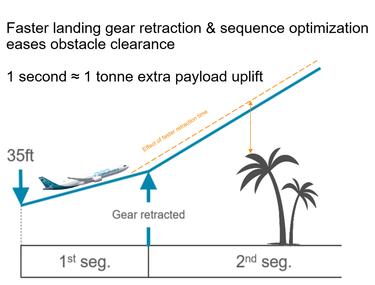

It should be noted that ETOC is coupled with another drag-reducing measure which reduces the first-segment climb duration. This reduction is targeted through two improvements: Shortening the landing gear retraction time by around 0.8 seconds; and reducing the landing gear doors’ opening & closing time by around 0.2 seconds. The modification consists of a new main landing gear (MLG) retraction actuator and flow hydraulic control device, plus new MLG door actuators.

As well as reducing the retraction time itself, the landing gear retraction sequence also commences a couple of seconds earlier after take-off than with today's aircraft. This shorter cycle is achieved via a new ‘Automatic Landing Gear Door Opening’ (ALGDO) function. When an engine failure is detected during take-off, this automatically commands the landing gear doors to open one second after lift-off. This is different to the current sequence in which the door opening sequence starts three seconds after lift-off, triggered by the landing gear lever.

Further A330neo enhancement studies

The A330neo’s development story does not stop here. Indeed, Airbus is already considering the next set of value-adding incremental evolutions for its customers, along two main axes: efficiency and sustainability. These include payload and performance optimisations, 100% SAF certification... and much more – so watch this space!

Your media contacts

Contact us

Martin Fendt

Airbus Corporate Communications - Airbus Commercial Aircraft

More about the A330

Continue Reading

A330neo: The Heir Apparent - Get ready for season 2!

Web Story

Aircraft

In each episode of Season 2, we will hear from senior leaders from A330neo customers, including Virgin Atlantic, ITA Airways, Condor and Cebu Pacific.

Volotea and Airbus sign a framework agreement on services

Web Story

Services

Corsair selects Airbus’ Flight Hour Services for its A330neo fleet

Web Story

News

Airbus launches mini docuseries “A330neo: The Heir Apparent”

Web Story

Aircraft

Airbus and Finnair complete large-scale A330 & A350 widebody cabin upgrade

Web Story

Services