For all Airbus aircraft types, it is the CIDS (Cabin Intercommunication Data System) which is the key system for the aircraft cabin and enables management of cabin lighting, passenger service system functions, EVAC (evacuation) signals, cabin interphone and cabin system monitoring. How does it work, what does it control and how can operators get the best system performance?

The backbone of cabin communication

The CIDS is the central digital data system for cabin crew to manage all cabin functions. It is quintessential in keeping passengers well informed and contributes to their overall comfort and safety. The CIDS allows control of cabin lighting, service interphone, EVAC signals and all functions of the passenger service system: passenger lighted signs, reading lights, passenger calls, automatic announcements, boarding music and the passenger entertainment system. The flight crew can monitor all cabin systems via a central interface.

System architecture and functions

The ‘classic’ CIDS was first introduced in 1988 for the A320 and has been installed in more than 2000 single aisle aircraft, many of them in operation today. This was the first time a single system integrated all cabin functionalities by connecting the crew, cockpit, cabin systems and passenger service. The core system architecture has remained robust and effective over 30 years of operation, while allowing for a seamless integration of updates and new functionalities like the SDF (Smoke Detection Function) due to its modular set-up. The adaptability of the system ensures viability for various aircraft types without major changes in hardware and with minimal training effort for its operators.

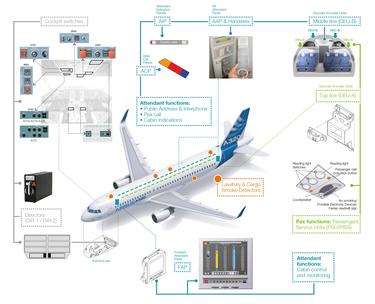

The system is typically managed by 2 Directors. They are the central computers of the CIDS. One operates in active mode and one in stand-by, so it can take over in the unlikely event of a complete failure of Director 1. The crew can control the cabin functions via the FAP (Flight or Forward Attendant Panel) or by using cockpit switches. Communication between the Director and the cabin, passenger and crew systems is handled via a number of DEUs (Decoder-Encoder Units). They pick up the information across the cabin and convert it into binary code for the Director. Binary code received back from the Director is then decoded. The DEUs are the interpreters enabling information transfer between the Directors and the cabin systems. They are spread along the cabin on top lines (DEU A) and middle lines (DEU B).

The system architecture is similar for all Airbus aircraft models.

The PTP (Programming and Test Panel) allows programming of the CIDS and running of functional tests. The system update for the A318 features no PTP as its functions have been integrated into a new touch screen FAP. The introduction of this enhanced CIDS on the A318 has been the starting point for its implementation on other models.

The FAP comprises the CAM (Cabin Assignment Module), the OBRM (On Board Replaceable Module) and the optional IPRAM (Integrated Pre-recorded Announcement Model) in compact flash card format. The IPRAM contains pre-recorded announcements and boarding music audio data that can be played in the cabin to passengers in accordance with operational requirements. The CAM defines all the modifiable system properties and cabin layout information for the CIDS. Each CAM is programmed according to the airline’s request, so the CAM is unique to every individual airplane. The OBRM contains the CIDS software. Major changes of the CIDS functions are executed by the replacement of the OBRM.

The ‘no smoking’ and seat belt signs are controlled directly from the cockpit while the cabin functions related to passenger service (for example, cabin lighting, temperature control and passenger calls) are managed by the cabin crew via the FAP.

A number of additional aircraft systems can be managed via the CIDS’ panels (FAPS, AAP etc.): emergency light, door bottle pressure monitoring, door closure status, slide armed/disarmed status, water and waste tank quantities, air conditioning and smoke detection. Starting with the enhanced CIDS, the SDF (Smoke Detection Function) has been embedded into the CIDS Director.

CIDS standard architecture

Even though the CIDS is not safety-critical itself, it remains important for flight safety. Prior to its introduction there was no communication system that handled operational and service-related data in an integrated data network. The reporting of information relevant to flight operations relied on the more or less effective verbal communication between cabin crew and cockpit. Today, awareness about communication cultures has been raised considerably, and an integrated cabin management system like the CIDS now helps flight attendants to report operational information, as there are sensors in place which already detect and communicate information to the CIDS.

As an example, an EVAC warning is automatically issued without any potential for human error through overlooking, misjudgement or miscommunication.

An evolving system with a classic core

- 1988: Launch of A320 aircraft with classic CIDS

- 1993: 700 aircraft of A330 and A340 model ranges

- 2003: 1500 aircraft equipped with enhanced CIDS for A330s and A340s

- 2006: Enhanced CIDS for single aisle, 8500 A318s, A319s, A320s, and A321s

- 2007: Adaption of CIDS for A380

- 2009: Enhanced 2nd Generation CIDS for A330 with integrated SDF function

- 2014: CIDS for A350

A resilient, adaptable and scalable original design allowed for integration of different standards for various aircraft types while keeping the classic system architecture intact.

Troubleshooting & maintenance for CIDS

Over its 30 years of operation, the CIDS has proved to be a highly reliable system for managing the increasing amount of cabin data and related cabin equipment. In case

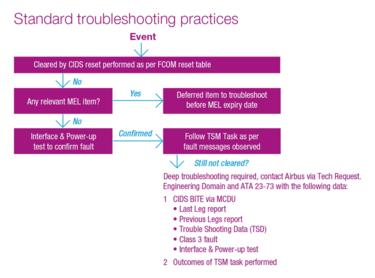

of a system fault or equipment malfunction event, there is a standard troubleshooting practice in place, which has to be followed. For the cabin crew this can happen when the system is used for passenger announcements or cabin interphone. The cabin crew then informs the flight crew, who performs a system reset according to the FCOM (Flight Crew Operating Manual) reset table.

If the initial event is not cleared by this standard reset the flight operator’s MEL (Minimum Equipment List) has to be consulted for a relevant item. The MEL will either identify the event as non-crucial to flight operations or provide an expiration date for deferred troubleshooting and fix. In case there is no applicable MEL item, or the event is classified as crucial to flight operations, a BITE (Built-in Test Equipment) test needs to be performed to confirm the fault and on-ground maintenance staff need to be involved.

The CIDS has an extensive self-monitoring capability. Failure messages related to CIDS units are sent to the CFDS (Central Failure Display System) or CMS (Centralised Maintenance System). Failure message reports are stored automatically in a CIDS BITE dedicated memory within the directors. Through three MCDU (Multipurpose Control and Display Unit) interfaces or OMT (On-board Maintenance Terminal) this information can be accessed from the cockpit. CIDS BITE enables interactive interrogation of the system by maintenance personnel.

The TSM (Trouble Shooting Manual) or AFI (Aircraft Fault Isolation for A350) will list the tasks to be followed for the observed failure message.

If the event is still not cleared, the issue requires deeper troubleshooting. At this point, contacting Airbus via Tech Request (Engineering Domain and ATA 23-73) is key for the required deep troubleshooting. A mobile app Tech Request was developed to facilitate reporting and feedback by the operators.

Reporting failure messages through Tech Request necessitates data from the CIDS BITE including the Last Leg report, Previous Leg reports, Troubleshooting Data (TSD), the Class 3 fault and the results of the Power-up test, in addition to the outcomes of the TSM task performed.

For general information ISI (In Service Information) reference guides are available for all CIDS versions ranging from the classic system for the A320 Family to the enhanced system for the A350 Family with the incorporated SDF function. The latest ISI guides can be obtained through the Resident Customer Support Manager or accessed via login to Airbus World.

Operators should note that these reference guides are frequently updated, nevertheless the AMM (Aircraft Maintenance Manual), TSM (Trouble Shooting Manual), FCOM (Flight Crew Operating Manual) and MEL remain the sole source of instructions during maintenance and operation

of the CIDS.

What will the future of CIDS look like?

The farthest-reaching impact on the future of cabin communication will be brought about by the new Decoder-Encoder Units DEU 4.0 linked with the Airbus data-integration platform, Skywise*. The (DEU) manage the information flow between the Director and the various cabin systems. The new DEUs 4.0 enable connectivity to the Internet of Things (IoT) and empower the CIDS for the digital transformation and ongoing fourth industrial revolution (Industry 4.0). It will pave the way for the wireless cabin, the ability to connect wireless equipment to the CIDS, and eventually create full digital connectivity for all CIDS related equipment. Data lake solutions will unleash an unprecedented potential for optimisation and customisation through real-time data management.

The future cabin management system will feature a simplified architecture, digitally connected equipment, customer feedback and data analysis tools.

The increased availability of data will not only help to further improve the systems operational reliability and facilitate handling, it will also unlock a great deal of relevant operational information for the airlines and allow for a new level of passenger service. Preferred lighting and seat settings from previous flights could be retrieved and reinstated and the In-Flight Entertainment (IFE) service could be targeted based on the passengers’ prior choices. Also, maintenance and troubleshooting in case of malfunctioning devices will be further facilitated, as enhanced more complete maintenance data will be accessible and directly presented in real-time.

The estimated release date for DEU 4.0 is 2023.

Conclusion

Since its introduction in 1988, the CIDS digital cabin management system has undergone several upgrades and adaptions for new aircraft types. Technical documentation is available to assist operators in improving operational reliability of the CIDS and onsite workshops have already proven to improve the reliability rate.

In the light of the upcoming link to Skywise and the advances in full digital connectivity and intelligent data management, the CIDS original system architecture remains relevant as an integrated single-system solution for cabin communications. The connection of the cabin systems to the Internet of Things and Skywise data lake will break new grounds in cabin communications, boost the CIDS’ self-monitoring capacity and open up new possibilities for creating and managing the passenger experience of the future.

Your media contacts

Contact us

Stéphane GUIRAUD

Smoke Detection System - A350 CIDS Specialist | AIRBUS

Thierry SCHENTEN

A320/A330/A340 CIDS Specialist | AIRBUS

Pierre MONTANIER

A320 Product Leader | AIRBUS