Designed for efficiency

The Airbus A350 Family is engineered to redefine operational efficiency for airlines and leasing companies. With a forward-thinking "designed-in" maintainability approach, the A350 delivers up to 25% lower maintenance costs over 15 years* compared to previous-generation aircraft, significantly maximizing aircraft availability and minimizing operational expenses.

From its initial design, the A350 was developed to ensure superior fleet management and operational performance. This commitment translates into:

- simpler, more reliable systems: engineered for fewer parts and higher reliability.

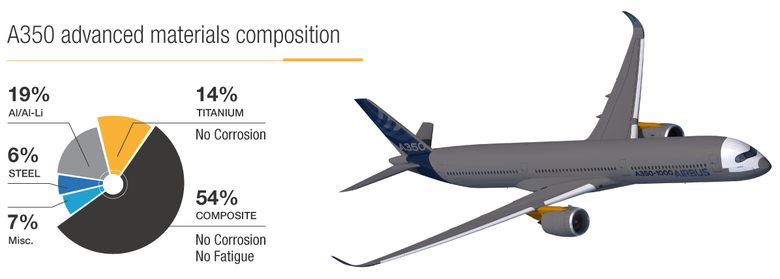

- optimal, advanced materials: reducing corrosion and fatigue risks.

- fewer maintenance tasks: extending check intervals and reducing downtime.

Simplified systems architecture

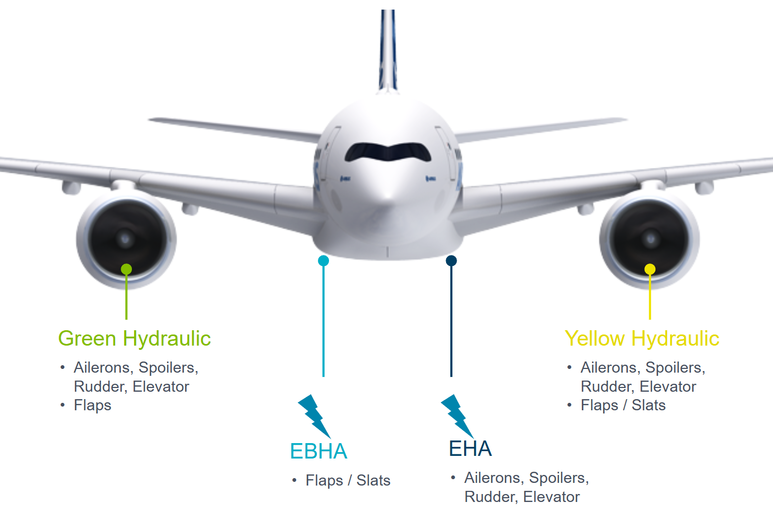

Maintenance is a primary cash operating cost. The A350 addresses this directly with efficient systems designed for lower maintenance. An example is its 2-circuit, 5,000 psi hydraulic system, replacing conventional three-circuit, 3,000 psi setups.

This simpler architecture significantly reduces the number of parts, improves reliability, and minimizes leakage risk, also contributing to lower aircraft weight and reduced fuel burn. Furthermore, the A350 utilizes modern Electro Hydrostatic Actuators (EHA) and Electric Backup Hydraulic Actuators (EBHA), allowing the removal of one conventional hydraulic circuit.

Innovations extend to modern variable frequency generators for power and electrically regulated bleed systems, boosting reliability and efficiency.

Fewer maintenance tasks, extended intervals

The A350 significantly reduces maintenance costs by reducing tasks and extending intervals. The strategic choice of advanced materials largely eliminates corrosion risks and significantly reduces the need for fatigue inspections across the airframe.

- Complex structural tasks every 12 years: major structural work, including cabin removal, is now required only every 12 years, doubling the interval of previous-generation aircraft. This ensures longer uninterrupted service.

- Extended landing gear overhaul: leveraging 34% titanium content, the A350's landing gear boasts a 12-year Time Before Overhaul (TBO) at entry into service, with a target of reaching 14 years – a leading interval in commercial aviation.

- Material longevity: composed of 70% advanced materials (53% composites, 14% titanium), the A350 requires no corrosion tasks for almost 70% of its structure, and no fatigue tasks for its composite elements, which are inherently fatigue-resistant.

Predictive maintenance and digital integration

The A350's sophisticated On-board Maintenance System (OMS) provides both diagnostic (Centralised Maintenance System - CMS) and prognostic (Aircraft Condition Monitoring System - ACMS) capabilities. The ACMS processes over 20,000 operational parameters, serving as the Skywise enabler for advanced health monitoring and predictive maintenance.

Seamless connectivity between the aircraft and ground operations via Airbus' Skywise digital platform enables real-time data flow. This allows for predictive interventions, streamlines line maintenance, and significantly reduces unplanned downtime, thereby maximizing revenue generation.

Rolls-Royce Trent XWB: unmatched reliability and efficiency

The A350 is powered by the world’s most efficient large aero-engine flying today: the Rolls-Royce Trent XWB. Having experienced the best entry into service of any Trent engine, the Trent XWB has now accumulated over 11 million flight hours at an exceptional 99.95% operational reliability.

The unique three-shaft design of the Trent reduces load flexing in the turbine and results in superior engine performance retention as well as better reliability and durability (time-on-wing).

The three-shaft layout also allows the fan to be positioned the optimum distance from the core to improve FOD (foreign object debris) deflection into the by-pass duct, further protecting the core.

Benefiting from the latest available technologies, the Trent XWB is not only a highly reliable, durable, low maintenance cost engine but also offers lower fuel burn, emissions and noise than comparable engines.

Conclusion: a new standard for your fleet

The A350's design, built on efficient systems, advanced materials, and enhanced reliability, sets a new industry benchmark for maintenance efficiency. For airlines and leasing companies, the A350 Family represents an unparalleled opportunity to optimize operational costs, minimize downtime, and maximize aircraft availability, securing a distinct competitive advantage for their assets.